Production

Wire cutter

We offer wire cutting to our customers as an additional technology at our major partner. It is possible to cut shapes into parts with a maximum size of 1000x800x400mm. The machines achieve a workpiece surface roughness of Ra 0.3. We are very flexible in terms of deadlines.

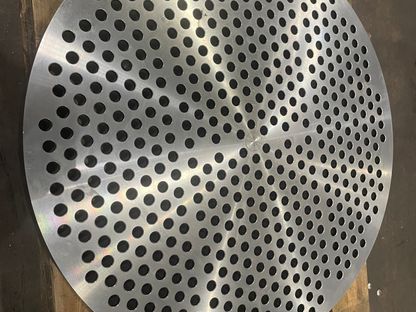

Deep drilling

All machines in our machine park can be used for deep hole drilling. We perform drilling from a diameter of 3 mm with a maximum length of 100 mm, up to a diameter of 100 mm with a maximum length of 2500 mm. We perform deep drilling both with oil lubrication and gun drills up to a diameter of 42 mm and a length of up to 3,000 mm, as well as drilling with special drills according to technological needs, e.g. a diameter of 96 mm and a length of 750 mm is not uncommon. In terms of material, we can drill aluminum, cast iron, steel parts and various composite materials.

Assembly and completion

After the production of individual parts, we also carry out the overall assembly of the assembly, if required. We also provide final surface treatment including anodizing, comaxit and wet painting, or other surface treatments.

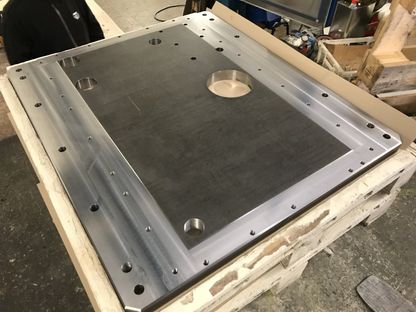

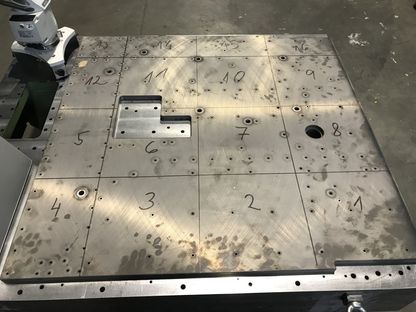

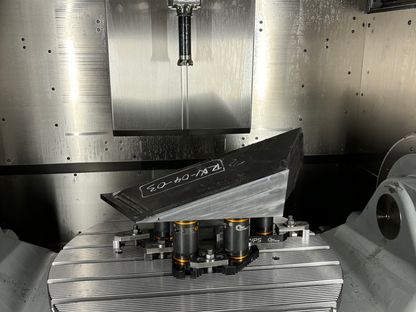

Machining of steel and aluminum plates

We process plates both from our plates (cuts, blanks) and from materials supplied by the customer. For processing steel and cast iron plate blanks, we have high-quality permanent magnets equipped with both movable and fixed pole pieces. For processing aluminum (alloy) plates, we have a vacuum fixture. For plates, we perform both thicknessing and final processing of parts. Maximum dimensions are 5000x3000x1500mm (lxwxh).

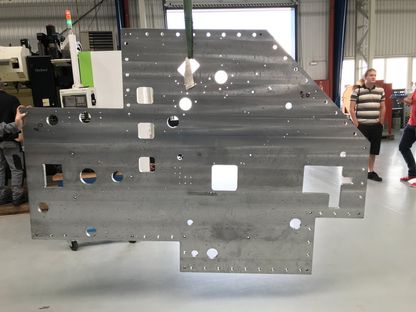

Aluminum machining

We machine aluminum and its alloys of various shapes, assembly jigs, blocks. We are able to rough and finish the blocks according to technological possibilities and we can also drill deep technological holes in them. We perform machining on the material supplied by us and also on the material supplied by the customer.

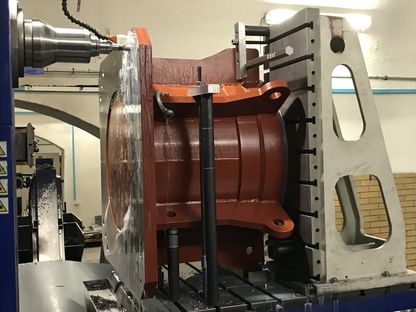

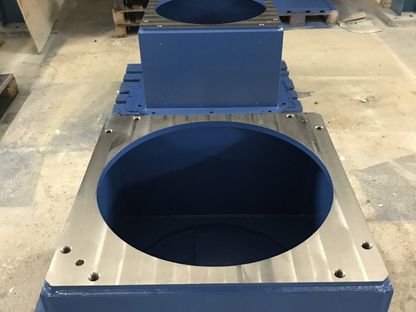

Casting machining

We machine both grey and ductile iron castings, as well as steel castings and very often also mineral concrete castings. Our most common products are gearboxes, bases of forming, cutting and other tools, parts of production machines and parts for special use. According to the customer's wishes, we are able to machine both castings supplied by the customer and all types of cast semi-finished products to be manufactured for the customer and subsequently machined. The maximum dimensions are 5000x3000x1500mm (lxwxh).

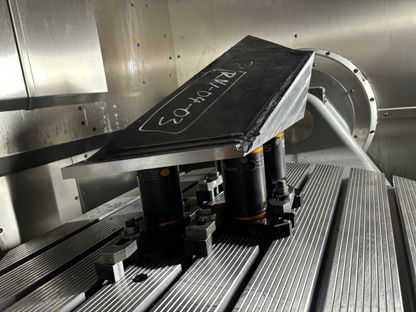

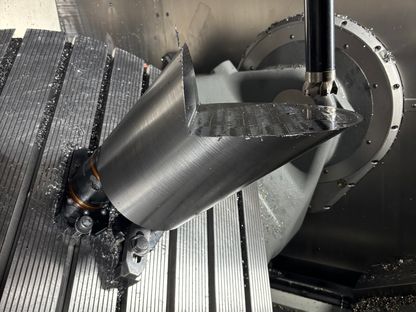

Machining of shaped parts

We produce shaped parts with a surface roughness of up to Ra 1.6. We program 3D shapes in CAM and prepare the complete technology ourselves. To achieve the desired shape, we use the kinematic capabilities of all machines (table, milling head) while maintaining maximum accuracy of the manufactured parts, without the need to switch workpieces, even for parts of considerable size.

Machining of special parts

Special parts are machined castings from mineral concrete, steel welds filled with mineral concrete, and also parts combined from a technological point of view. Most often, these combinations are a set of technologies of carouseling, machining on a horizontal boring machine and on a gantry center.

Turning

We perform turning on our own MAZAK turning centers. Thanks to the bar feeders, the machines can be used both for serial production, numbering several tens of thousands of pieces, and for piece production. Thanks to the counterspindle, we are able to machine even the most complex parts. Thanks to the many positions of the driven tools, the machines allow both off-axis and perpendicular drilling and milling to the main turning axis.

Large diameter turning

We perform carouseling of parts as an additional technology for further machining of parts, as well as as a final technology. We perform this machining at a long-term partner who has a very precise and powerful carousel from the manufacturer TOS Hulín. Parts up to a diameter of 2500 mm and a height of 1200 mm can be turned.

Welded parts

We use several reliable regional partners for the production of weldments. It is possible to weld parts weighing up to 20 tons and measuring 5000x5000x2000mm. After welding, we are able to anneal, blast, paint or do other surface treatment according to the customer's wishes. We can draw the welded parts into individual sheets with the preparation of substrates for sheet metal burning.

Sparking of bent cutting tools

We perform electroerosion machining with high precision and very high-quality achieved surface roughness. This includes, for example, sparking grooves for keys, grooving, complicated shapes that cannot be achieved by chip machining. The maximum possible dimensions of parts are 2000 mm x 1500 mm x 500 mm thanks to non-standard baths.

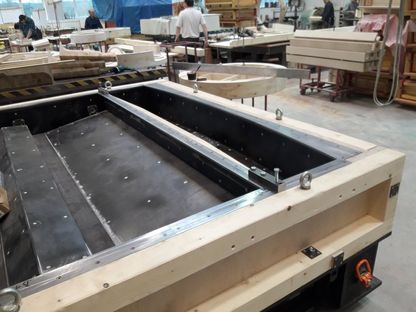

Production of model devices

Complete production of model equipment for casting gray and ductile iron. Also for casting steel, aluminum and mineral concrete castings. We ourselves draw up the complete model equipment based on the drawing of the final casting. It is possible to design the service life of this equipment based on discussions with the customer and thus make the most effective use of the invested costs. We also perform completion, reconditioning and changes to the original model equipment.